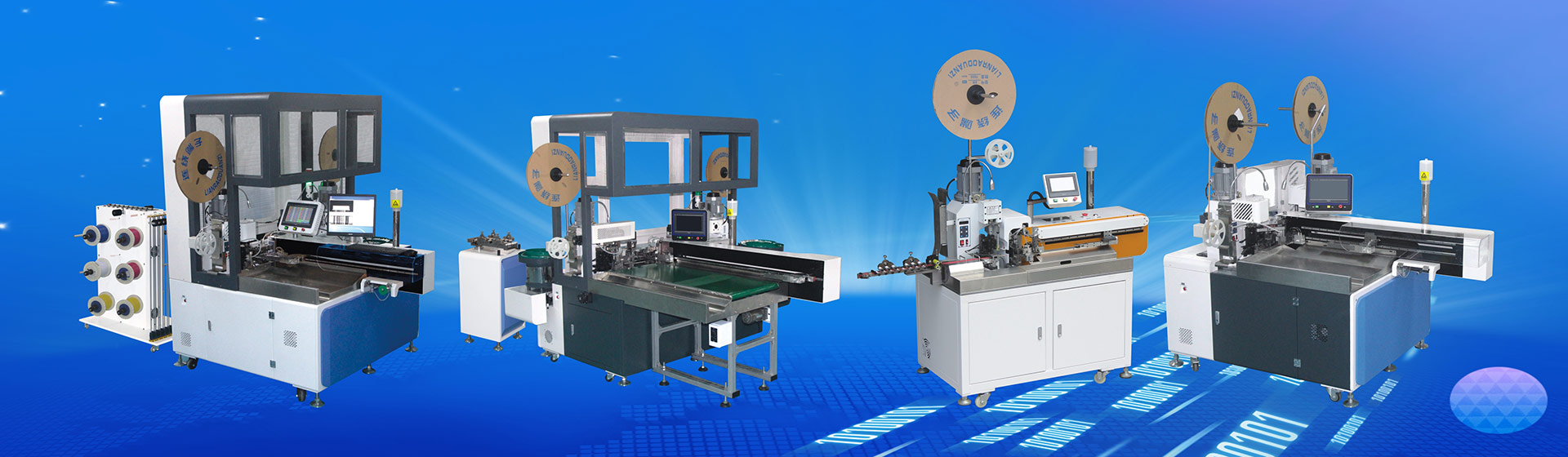

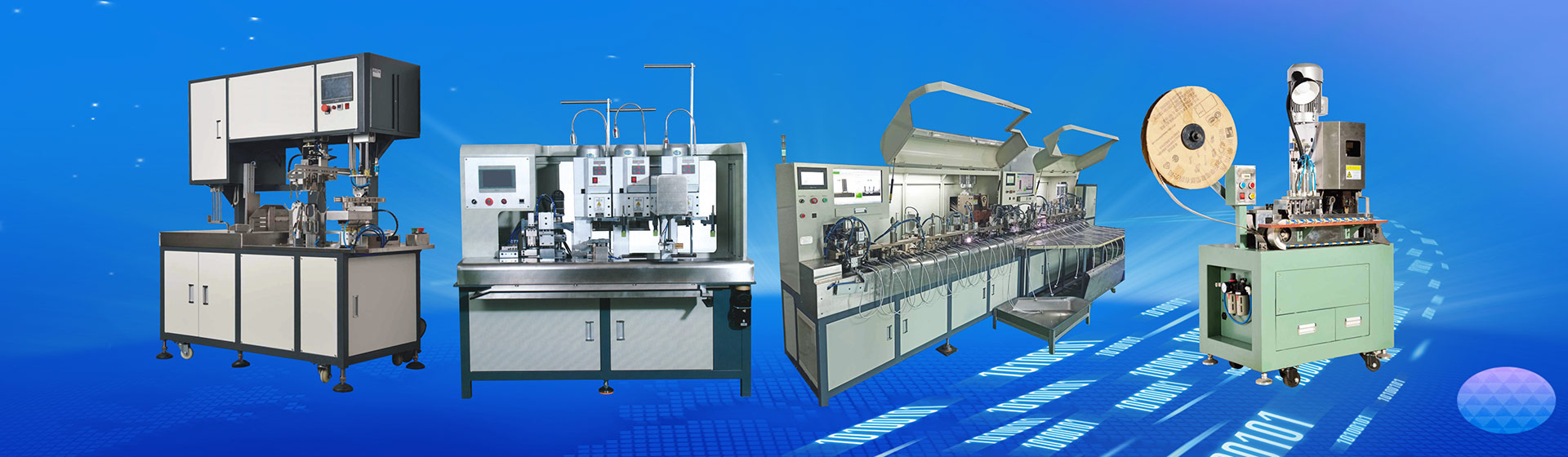

Overview: Full-automatic terminal machine refers to a kind of wire processing application, also known as active peeling and pressing machine. It is a new equipment in recent years. It has a set of multi-function machines, including feeding, cutting, peeling and crimping. It is a humanized and intelligent high-end technology product, suitable for large, medium and small enterprises, and saves labor.

2 Product characteristics

High precision, fast speed, and stripping, distortion and end pressure detection system. Digital control interface, light, electricity, gas, machine application, magnetic integrated operation machine, imported electrical appliances and accessories, easy to operate and save time.

3 Product classification

Fully active terminal pressing machine; Fully active dual-terminal machine; Active crimping and twisting wire welding terminal machine; Fully active double voltage twisted wire welding terminal machine; Non-standard active terminal pressing machine is customized according to customer requirements

4 Operation steps

1. Turn on the power terminal switch, and the power indicator light starts to use it.

2. Pay attention to the fact that there is no obvious abnormal sound in the internal and external machines. If there is a suspension of operation and it is necessary to stop, ask the maintenance personnel to admit whether it is necessary to repair.

3. Carefully selected knife: operated by the designated personnel, it is necessary to compare the support of the blade by hand. After the comparison of the knife is correct, it is necessary to use manual test. First, close the power terminal machine, press the button, and use a special wrench to shake the driven pulley terminal machine. The stamping stroke is the largest, if the hand is not moving, then consider whether there is excessive pressure or other problems, check and debug it. In the lock screw, the corresponding check and acknowledge that there is no need for loosening.

4. Pay attention to charging: the demand hits the terminal equipment, and the Allen wrench adjusts the use of the feed plate, so that the terminal can easily pass through, whether to send the appropriate visual material position, if not, adjust, use the hex wrench to loosen the locking screw feeder, dynamically adjust the rod adjustment of the screw diameter until the best, and then lock the screw and start to move.

5. Tensile testing machine: well, when testing the scrap wire, the tensile test, see the detailed operation method of the "tensile test bench" as follows. The primary reference value is to reset the zero key of the tension test, and test the electric clamp of the terminal wire test. If the measured tensile force is not within the specification, please adjust it by the maintenance personnel until it reaches the specification value. 6. The 10 pieces produced will be sent to IPQC for the first piece recognition, which can be checked and can be produced in batches. During the production process, it is necessary for the terminal operator to check whether there are plastic bags, hanging and other defects, and a terminal tension test will be conducted every 1 hour.

5 Maintenance protection

Daily protection

The guide rail of the terminal press should have lubricating oil holes on the top of each terminal for 1 hour. 2-3 drops of air are appropriate, not too much. It is necessary for operators to clean the machine every day. The debris and residual grease on the surface of the dust remover are the most important. It is necessary to add butter to the high-speed bearing terminal every week. The detailed operation method is as follows: open the rear cover of the terminal machine, remove the snap ring and remove the driven pulley, apply butter (evenly on the surface of the high-speed bearing), and recover (note: in this process, pay attention to the loss of the bearing ball during the removal of the pulley). The terminal machine will be used for 3-6 months after two-stage maintenance, It is required to check whether all parts (losses) need to replace accessories such as belts, and springs replace those with less elasticity. Check whether the mechanical locking screw is loose and whether the spring is deformed.

6 Precautions

1. In the process of operation, if the machine is abnormal, close the power supply and timely ask the maintenance personnel to repair and debug.

2. Non-designated personnel shall not debug or disassemble machine parts.

3. During the operation, the power supply of the machine has been cut off. It is forbidden to enter the punching scale with fingers or any part of the body to prevent accidents.

4. In the operation, if you need to leave, please turn off the power before leaving.

5. For terminal replacement, it is necessary to disconnect the power supply first, and then replace it. Strictly stop the replacement machine operation.

6. In the process of operation, if the terminal card is in the knife mold, it is necessary to use scissors or needles to take it out and continue the operation.

Navigation

- News

- Company News

- Industry News

- FAQ

Contact Us

-

Chinese Mobile:+86-18937775181

Automatic terminal machine is introduced